Prototyping Solutions

Overview

Microsemi offers a wide variety of prototyping solutions for space FPGAs such as RTG4, RTAX-S/SL/DSP, RTSX-SU and RT ProASIC3. These solutions provide designers of space-flight systems with a prototyping vehicle for every step of the design phases, ranging from cost-effective commercial-equivalent devices in commercial packages to RT-PROTO devices using the same silicon and package as the flight units without some flight-model tests. Our prototyping solutions help speed up the design and verification process while making it easy to use Microsemi space FPGAs even in the most complex design which requires multiple phases of verification. Below are the solutions that we offer for each device family and all the documents to assist with Microsemi space FPGAs prototyping:

| FPGA Device Family | Reprogrammable Aldec Solution with Adapter Sockets | Commercial Device in Commercial Packages, with Adapter Sockets | Commercial Device in Ceramic Packages | RT-PROTO |

|---|---|---|---|---|

| RTG4 | x | |||

| RTAX-S/SL | x | x | x | x |

| RTAX-DSP | x | x | ||

| RTSX-SU | x | x | x | |

| RT ProASIC3 | x | x |

RTG4

RTG4 PROTO FPGAs offer a development and prototyping solution than can be used for development and final timing validation of the flight design. As the RTG4 PROTO units use the same reprogrammable Flash technology as the flight units, the PROTO devices can be reprogrammed many times without removing them from the development board.

RTG4 PROTO devices use the same silicon and the same packages as RTG4 flight-model FPGAs. RTG4 PROTO device programming is currently enabled in Libero SoC Design Suite. When designing for RTG4 PROTO, customers can use the same device setting in Libero SoC software as for flight models.

The RTG4 PROTO prototype units have the same timing attributes as the RTG4 flight units, including support for the same speed grades as the flight parts. The RT-PROTO units are electrically tested in a manner to guarantee their performance over the full military temperature range. Prototype units are offered in non-hermetic, ceramic packages.

The prototype units include "PROTO" in their part number, and "PROTO" is marked on devices to indicate that they are not intended for space flight. They are also not intended for applications that require the quality of spaceflight units, such as qualification of spaceflight hardware.

RT-PROTO units offer no guarantee of hermeticity and no Mil-STD-883 class B processing. At a minimum, users should plan on using class B devices for all qualification activities.

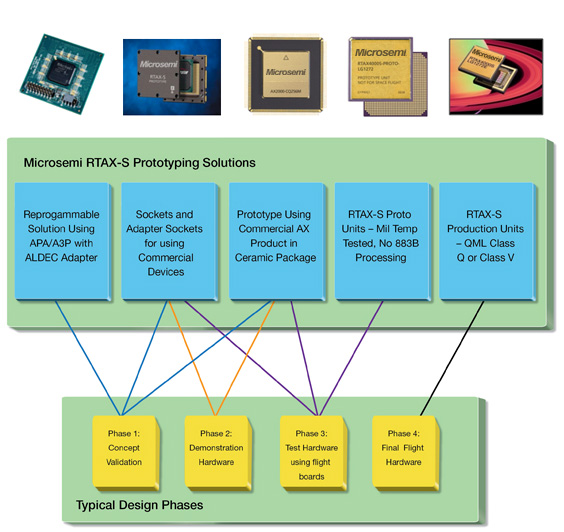

RTAX-S/SL

For the early development phase and functional verification, Microsemi offers commercial Axcelerator products as a cost-effective way to prototype for RTAX-S/SL designs. Most RTAX-S/SL products have a footprint-compatible equivalent device in the ceramic package that customers can use for prototyping. For those package types that do not have footprint-compatible Axcelerator equivalent devices, prototyping adapters are offered to pin-map the Axcelerator devices to RTAX-S/SL package footprints.

In these early phases, customers can also prototype with Microsemi's flash-based reprogrammable ProASIC3 devices. Aldec provides the software that remaps antifuse primitives to flash which reduces design time and cost. In addition, the hardware adaptor is foot-print compatible with RTAX-S/SL, and therefore, a customer does not need to redesign a new board for prototyping. For more info, refer to AC170: Prototyping RTAX-S Using Axcelerator Devices App Note

For final design verification, Microsemi offers the RTAX-S/SL/DSP PROTO units that have the same footprint and timing characteristics as the flight unit. The RTAX-S/SL/DSP PROTO units guarantee performance over the full military temperature range. These solutions offer tremendous savings in design time by eliminating design cycles, which translates into overall lower development costs.

RTAX-DSP

Prototype versions of the RTAX-DSP devices are available as RT-PROTO devices. These parts use the same silicon with the same timing as the space-flight qualified units. Hardware timing verification on prototype devices is performed across the full military temperature range (-55°C to 125°C). The prototype devices also have the same pin assignment and mechanical footprint as the flight-qualified devices. However, while the prototype devices are assembled in ceramic packages, no MIL-STD-883 Class B processing is performed. Hermeticity is not tested nor guaranteed. Therefore, the prototype units are not intended for engineering qualification or space flight and should not be subjected to thermal vacuum testing nor should they be assembled onto boards intended for space flight.

Other prototyping solutions for RTAX-DSP space-flight FPGAs can be available through our partner Aldec. Contact Aldec for more information.

RTSX-SU

A lower cost prototype solution is available for RTSX-SU devices that utilize commercial SX-A devices. The SX-A prototyping solution can offer either footprint-compatible packages or prototyping sockets to adapt commercial SX-A packages to the RTSX-SU package footprints. For final hardware verification, RT-PROTO is also available.

RT ProASIC3

RT ProASIC3 devices in the Land Grid Array (LGA) and Ceramic Column Grid Array (CCGA) packages are pin-compatible and timing compatible with the commercial equivalent ProASIC3EL devices in Fine-Pitch Ball Grid Array (FG) packages. For example, to prototype a space-flight design intended for RT3PE600L-CG484B (RT3PE600L in the Column Grid 484 package), designers should use A3PE600L-FG484M (A3PE600L in the Fine Ball Grid 484 package). The use of the M version (military temperature range) ensures that timing can be verified in hardware across the full temperature range from –55°C to 125°C. Since ProASIC3 FPGAs are reprogrammable, only a very small number of prototyping devices need be purchased.

RT-PROTO is another prototyping solution which offers the same package and timing characteristics as the flight units. RT-PROTO is the only prototyping solution available for RT ProASIC3 devices in the Ceramic Quad Flat Pack (CQFP) package. The biggest advantage of the RT ProASIC3 FPGAs is re-programmability, allowing easy testing and prototyping as the prototype units can very well be the final flight products.

Documents

| RT-PROTO Description |  |

270 KB | 9/2015 |

| AC170: Prototyping RTAX-S Using Axcelerator Devices App Note |  |

1 MB | 1/2013 |

| AC195: Prototyping for the RT54SX-S Enhanced Aerospace FPGA App Note |

|

412 KB | 6/2012 |

| Prototyping Solution for FPGA Devices Brochure |  |

8 MB | 11/2011 |

| AC274: CQFP to FBGA Adapter Sockets App Note |

|

5.2 MB | 12/2016 |

| AC275: CCGA TO FBGA Adapter Socket Instructions App Note |

|

2.7 MB | 11/2011 |

| AC341: Microsemi CCGA to CLGA Adapter Socket Application Note |  |

625 kB | 12/2016 |

| AC342: CQFP to CLGA Adapter Socket Application Note |  |

1 MB | 12/2016 |

| Mechanical Drawings for the RTSX Adapter Board |  |

253 KB | 6/2013 |