Package Miniaturization Services

Overview

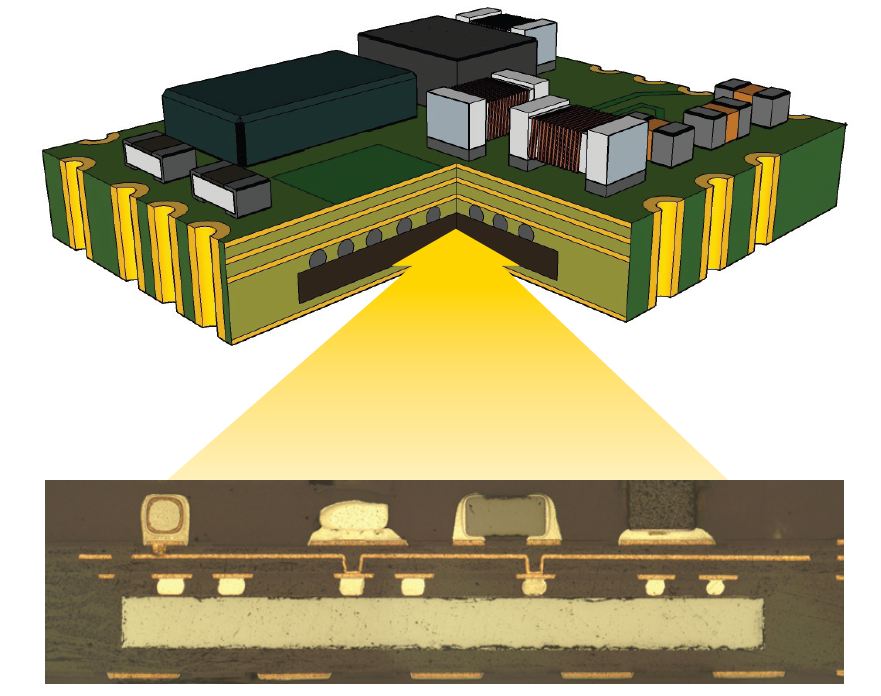

Microsemi's Package Miniaturization Services utilizes the Large Area Panel (LAP) - based Embedded Die technology to perform sub-system size reduction levels that cannot be achieved via standard chip-on-board technology. Microsemi's Embedded Die technology offers quality, reliability, security, and allowing practical implementations of systems on a package with real-estate savings of 70% vs the original PCB area.

Microsemi's Package Miniaturization Services utilizes the Large Area Panel (LAP) - based Embedded Die technology to perform sub-system size reduction levels that cannot be achieved via standard chip-on-board technology. Microsemi's Embedded Die technology offers quality, reliability, security, and allowing practical implementations of systems on a package with real-estate savings of 70% vs the original PCB area.Embedded Die Technology Features and Benefits

| Feature | Benefit |

| Die "zero area occupancy" | Reduce size or Increase functional density |

| 3D die stacking | Vertical integration offers additional size reductions |

| Flip chip, wire bond or packaged part | Flexible system integration |

| Custom package design | Adapt package to meet customer board requirements |

| Low tooling cost | Fast turnaround for custom design services projects |

| Mechanical barrier supporting the die | Package robustness |

| MIL-standard for Implantable devices compatible | Highly reliable |

| Hidden die | Increased security against counterfeiting |

Embedded Die Technology Applications

- Medical Implants

- Medical Wearable Devices

- Sports/Fitness Devices

- Security

- Military

- Industrial Sensing

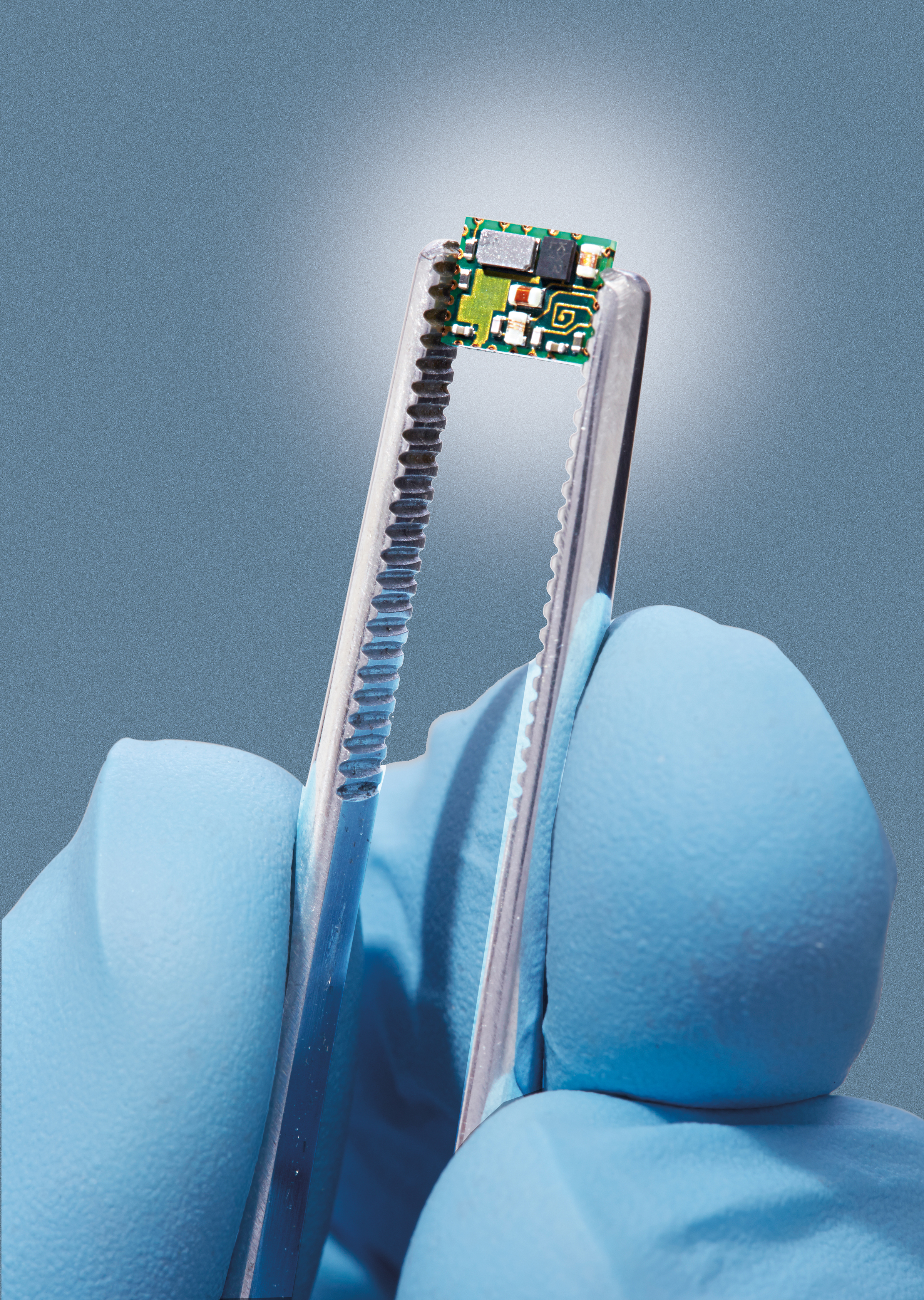

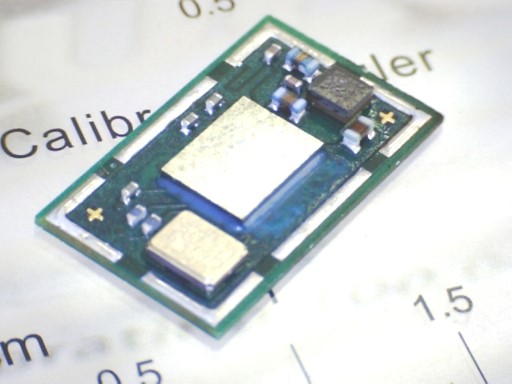

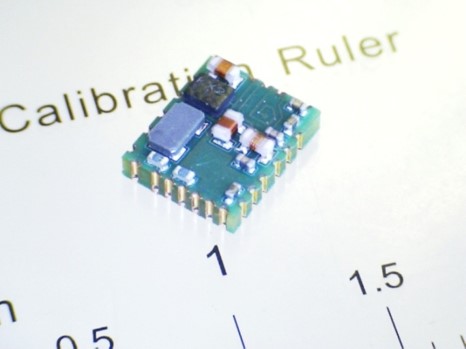

ZL70103-based Package Miniaturization with Embedded Die Technology Example: ZL70323 Radio Module

Microsemi offers an RF Standard Implant Module (SIM) based on the ZL70103 MICS telemetry device for implant OEM’s looking to speed up the development cycle and mitigate risks by using an approved design. The emerging Neuro-Stimulation OEM‘s needed to develop smaller devices to aid patient comfort. To meet this need, Microsemi's Package Miniaturization Services group took the existing SIP design and used the Embedded Die technology to integrate the ZL70103 in to the substrate. The support components fit within the area of the die, enabling a near zero area die occupancy. This enabled a module footprint reduction of 70%.| Standard System in Package (SIP) technology | Embedded Die Technology | |

| Area: 12mm x 7mm = 84mm2 | Area: 5.5mmx4.5mm = 24.75mm2 | |

|

|

|

Package Miniaturization Services Offering

Design & Realization

- Customer specification generation

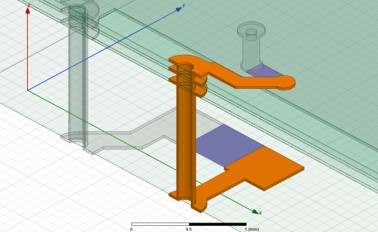

- Mechanical and electrical package design

- Circuit Layout and simulation

- Mechanical stress and thermal analysis

Prototype to Full Production

- Definition and execution of product validation and verification process

- Product engineering – cradle to grave

- Product realization (components, manufacturing)

- Process and Equipment engineering

- Tooling / fixture design

Test

Test

- Production test system development

- Mixed signal electrical test (Eagle, Syncro, RF Catalyst, Custom Rack & Stack)

- Traceability back to individual silicon wafer number

- Group A,B,C & D qualification testing, X-ray and Cross sectioning

- Burn-in ovens – production and component screening